Company

Since 1955, our family-owned company has been developing, producing and distributing high-performance ultrasound equipment as well as matching accessories and cleaning and

Disinfection preparations for the industrial, medical and laboratory sectors. Due to the very wide range of products for ultrasonic cleaning and also the implementation of process engineering processes, we are perceived as a full-range supplier for the ultrasonic sector. The high degree of specialisation in the versatile applications enables optimal solutions for our customers.

Guiding principles & core competences

Principles of our corporate culture

As an innovation-oriented medium-sized company in its third generation, we put promising long-term solutions first. The products and processes perfected over many years are reproduced with the highest precision and adapted to the ever-changing framework conditions.

Added value for our customers

The result of our work is reliable and robust products that always perform well even under demanding conditions of use. This guarantees our customers smooth and economical operation of their own business activities.

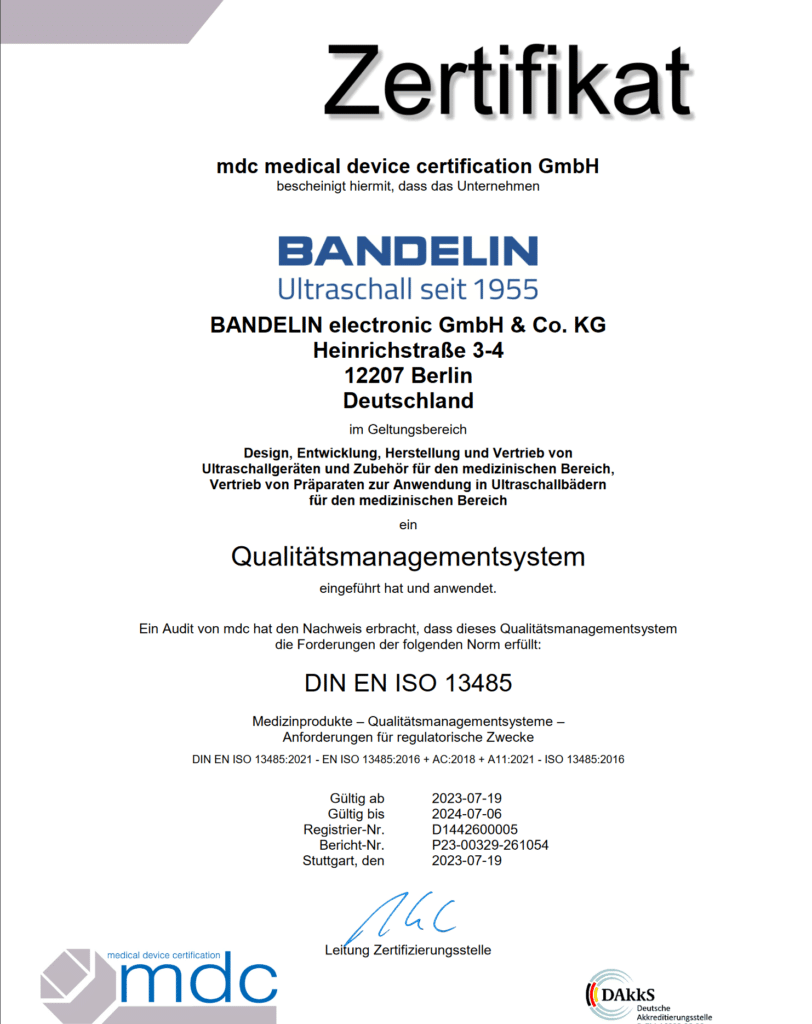

Certified

In order to ensure the quality of our products and the satisfaction of our customers and users in the long term, we have maintained a quality management system since 1996. Certification in accordance with the DIN EN ISO 9001 and DIN EN ISO 13485 standards is a matter of course for us.

Economical and efficient

Due to the high quantities, we can offer series devices at an attractive price-performance ratio.

professional advice

If a repair is needed after many years of use, we can provide you with a quick repair in our company. We will be happy to advise you on applications and special uses of ultrasound. Our experts create customised solutions for your specific application.

Family business in the third generation

Product solutions from a single source

You receive a product perfectly adapted to your specific ultrasonic application. Due to the modular combinability as well as the application reference of the product series, special applications can also be served that are only available from us.

Individual

The realisation of customised special solutions is one of our strengths. You receive a product perfectly adapted to your special ultrasonic application. Due to the modular combinability as well as the application reference of the product series, special applications can also be served that are only available from us.

Quality at the highest level

Our customers have a decisive influence on the development and manufacture of our products as well as on the high quality standards that every product from our company must meet. This is ensured by quality tests in all production stages as well as by a 100% final inspection.

Development, production and distribution in Berlin

To ensure the highest quality and at the same time flexibility in new developments, we are constantly working on increasing our vertical range of manufacture. The entire manufacturing process from stainless steel sheet to the finished ultrasonic bath takes place at one location. Due to the highly integrated value chain, we can also realise small quantities at an attractive price-performance ratio for our customers.

The constant investments in modern production machines pay off with efficient production and high parts precision. A strong sense of belonging and low staff turnover are guarantees for sustainable knowledge retention and transfer to the next generation. The close cooperation between development, production and sales enables direct exchange and optimal fulfilment of customer requirements.

Trainings

We impart expert knowledge about ultrasound devices and their application in practice as well as on-site service. You will receive numerous tips on applications and how to avoid application errors. The content of the training courses is tailored to the requirements of the participants.

Repair

In case of a defect, the units can be repaired by our most experienced staff. For the repair of our durable products, a large quantity of spare parts is stored with us.

Quality management

For device qualification as part of your quality management or validation, you will receive documents for your IQ/OQ documentation for all device types.

Prospects at Bandelin

Quality management

For us as a manufacturer of medical products, quality and safety have always been the focus. For more than 25 years, our quality management has been certified according to the DIN EN ISO 9001 and DIN EN ISO 13485 standards. Regular monitoring and recertification serve to continuously improve our quality management and to meet the growing demands placed on us and our products.

Commitment &

Association activities

Development and innovation

Custom-fit equipment with ultrasound

Since the early days of the company, constant innovation and improvement of the customer benefits of the products have been the core of the company's success. In addition to the further development of proven products, the company has developed unique complete solutions in the field of high-performance ultrasound. These include highly specific equipment for instrument preparation, which enables the simultaneous rinsing, movement and ultrasonic cleaning of increasingly complex robotic instruments. A comprehensive range of accessories such as shakers, movement units, noise protection boxes, sonication vessels and cooling solutions has been developed around the topic of "sample preparation using ultrasound in the laboratory". These prepared applications offer customers an uncomplicated introduction to new analytical methods.

Laser punching of the tub parts

Milling the swing elements

Ultrasonic generators

Welding the tubs

Control of the intermediate products

Assembly of the generators

Bonding the swing elements

Wiring the units

Final assembly

Finished product

Production

From raw material purchasing to final assembly

From the stainless steel sheet to the ready-to-use unit, the entire manufacturing process takes place at our site. This historically determined, particularly large vertical range of manufacture enables a high degree of specialisation of the employees in the specific quality requirements of ultrasonic devices. In addition, it guarantees a high degree of flexibility with regard to innovations and customer-specific solutions. Modern machinery for the production of series and individual parts creates additional efficiency and flexibility. The manufacturing processes perfected over several generations guarantee high product continuity and quality. With their know-how, our qualified employees ensure that components are optimally manufactured and processed at every machining station. We meet the special requirements for the precise machining of stainless steel components through regular training of our employees. With the help of new technologies, we are constantly developing the manufacture of our products in order to be even more economical, precise and, above all, future-proof in the future.

Social engagement

Customised superstructures

Custom-fit equipment with ultrasound

In addition to the wide range of series products, we offer our customers the possibility of equipping individual designs with our high-performance ultrasound. The ultrasonic vibration systems can be firmly connected to almost any flat metal surface with a diameter of at least 50 mm. Depending on the desired performance and size of the individual ultrasonic system, a variety of ultrasonic vibration systems can be applied to your component.

OEM/OBL

Our quality - your brand

Are you interested in high-quality ultrasonic baths, but do not have your own manufacturing capabilities? The solution is an OEM or OBL product. Here, almost all ultrasonic baths in our range can be customised in appearance. Adaptations can be realised with individual front plates, type plates and customer-specific instructions for use. We already have close partnerships with renowned dealers from various sectors and other manufacturers who expand their own portfolios with ultrasonic baths with their own brand or company logo, taking advantage of BANDELIN's high level of experience and manufacturing expertise. Our team will be happy to support you in a personal consultation in addition to the selection of equipment that is right for you, also in the design of the OEM / OBL agreement.

We also participate in the

ENVIRONMENTAL PROTECTION

Combined heat and power plant

LED conversion

Photovoltaic system

Quality since 1955

We - a Berlin-based family business in its third generation - specialise in the development, manufacture and distribution of ultrasonic devices, corresponding accessories and application-specific cleaning and disinfection preparations. The high vertical range of manufacture, a modern production facility and motivated employees distinguish us and are guarantors for constantly new quality products.